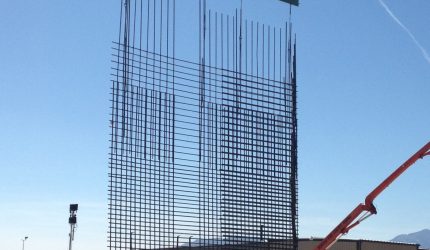

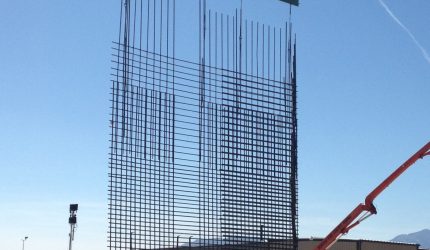

Ground up construction of a 22,000sf chrome plating facility. One of three in the world. Building had locker room facilities, a complete chrome plating infrastructure including air scrubbing and waste treatment facility, two free standing three floor ventilated mezzanine structures to hold 32 rectifiers per plating operation, a 70 foot eave height for five crane bays, (3 current, 2 future) capable of holding fifteen interlocking underhung bridge cranes (6 current, 9 future) and two 50ft deep pits for vertical acid tanks used in the chroming process. Two 2500kVA services supply the current building configuration; a new 12inch water main services the new 10inch fire loop and new domestic water lines. Building designed and built with the future expansion capability including infrastructure for a third 2500kVA service, a second pit/mezzanine structure and future crane capacity that will double the current output.

Experience

Weatherford International

Project Gallery